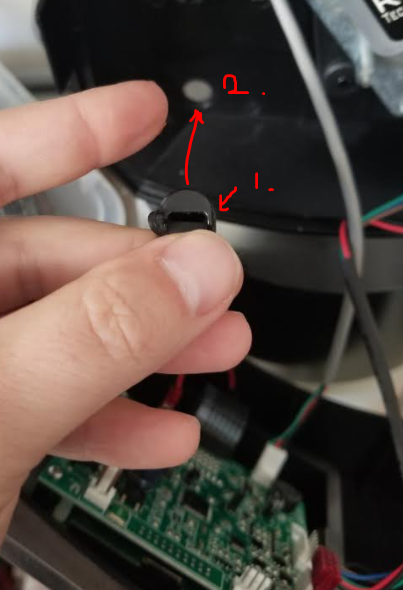

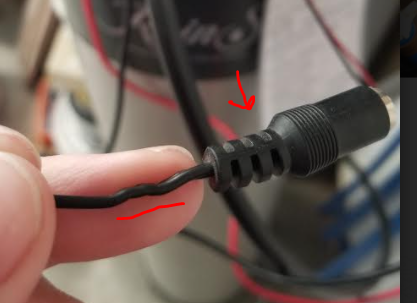

Well that’s easy: A Crimp, or an electrical connection. As seen below from my latest: COVID let’s fix everything around the home. You can see that even a power supply connection can fail. In this case the strain relief may have had something to do with it.

- Plastic strain relief (too tight on cord)

- The only thing this helped is for the female plug to not pull out.

Once I noticed the power was not on (my water wasn’t soft.) It’s time to look at the PCB. Any noticeable burns? No, it looks fine. Is there power at the incoming power jack? No. Is there power at the wall mount power supply, Yes, is there power from the power supply jack? yes. Ohm time…. is there a connection from the strain relief jack to the molex connector on the PCB? No… Well one side was connected the other wasn’t. FOUND!

Next step: replace the barrel jack connector. I cut and re-soldered a new barrel jack into the good side of the wire harness.

***Before you do this always check to see if polarity matters. Especially if the power supply is DC. Mine was BUT I just used the multimeter to check incoming power to a diode bridge. If you have that at the input of your PCB it really doesn’t matter which way you put power to the circuit board.

Once I plugged in the power everything was happy again! Another option would be to eliminate the connector altogether and solder right before the power connector. You still would need strain relief as if the power supply was dropped the PCB could pull the molex plug off the inside of the box. It is cheaper but replacing the power supply is more of a pain.

As I used to work out in the field a lot looking at issues with product the most common problem would appear after vibration of shipping or road vibration and it was usually at a connection point. Hope you liked my post!