My Brother owns a farm and had a simple problem about a low pressure water irrigation system. It went like this: I have 50 lines at 415 feet,(low pressure) so 20,775 ft total. Divide that by 100 is approximately 208 kft. Times by 0.45(gpm per 100ft) equals 94 gpm. Using 100 gpm for the whole system. Each line can be shut off. The issue came about when he thought the designer of the system had messed up because the motor was running above the Service Factor. The next thing to note was the ditch water and the dual filter system also has to be modeled. The original attempt over the phone looked like this:

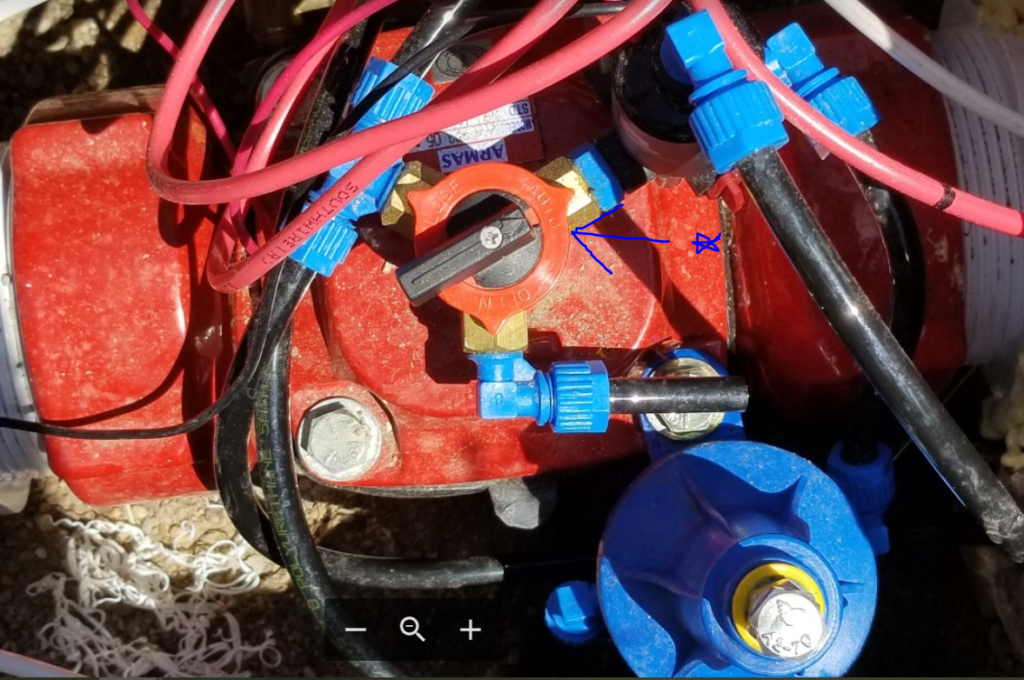

Needless to say he didn't mention how he went from the high pressure of the motor to the low pressure and multiple zones. So that changed the schematic quite a bit. We will see the final design at the end. How we troubleshot the system was to turn off zones which will increase pressure. The pressure regulator should keep the pressure constant at the low pressure side. We can see pressure on both sides, luckily, and they were equal all the time. This means the pressure regulator was not working.

This is one problem: the diagram can wear out and not pressure regulate. This one was just fine:

Three settings on this. Auto, open, and close. Open is what you think. Wide open, closed the water pressure goes to the moon. Why? Because it is closed. Auto means you can adjust it. Auto means your controller will bring it in. Bottom line you can’t find anything on the internet about how this works. So hopefully this is helpful. You can adjust the bolt on the plastic blue thing to set the water pressure. But if the whole system has the same pressure on both sides of this regulator you have a problem.

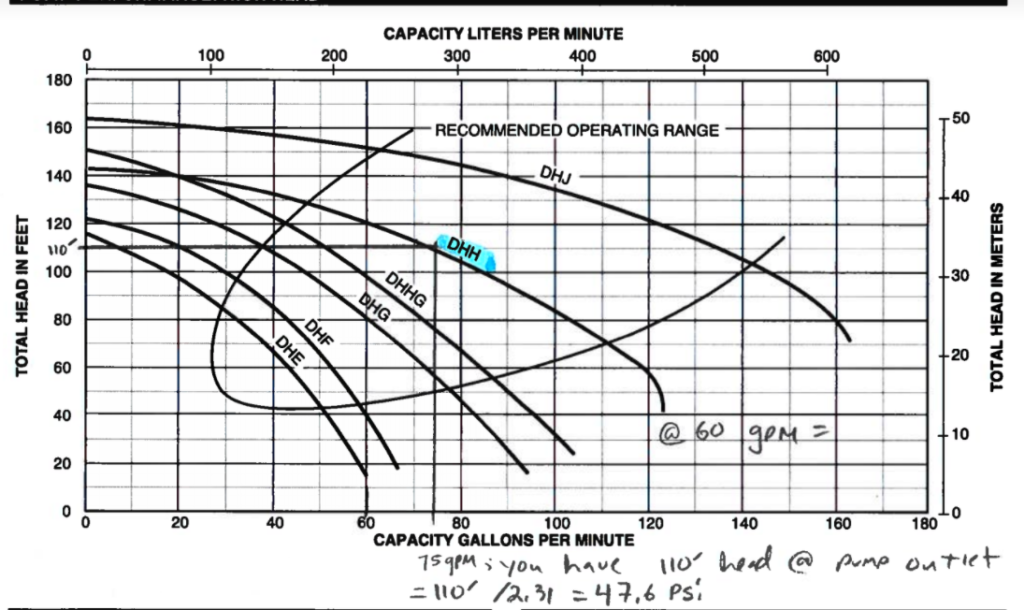

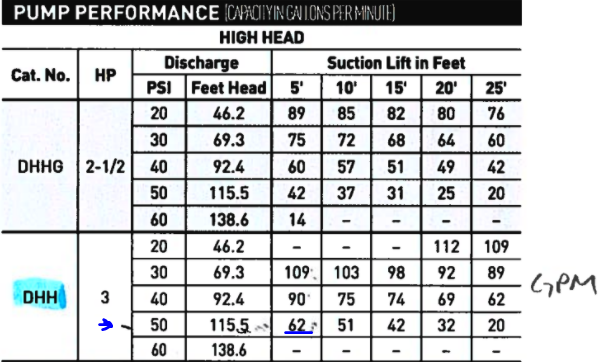

The pump curve is showing that at 75 gpm the pressure coming out of the pump is 110’ of head or ~47.6 psi.

At ~47.6 psi and between 5ft to 6ft in suction I estimated the motor could output about 50-60 GPM. As water moves down a pipe the resistance on the walls will lower the GPM. This is why the 800 plus feet of pipe was 3 inches in size. This is also why we model this line with a resistor. The pressure regulator is modeled by a voltage regulator and the motor is modeled as voltage. GPM is equal to current. PSI is equal to voltage. Here is the final schematic and I’m happy to report everything is working properly.